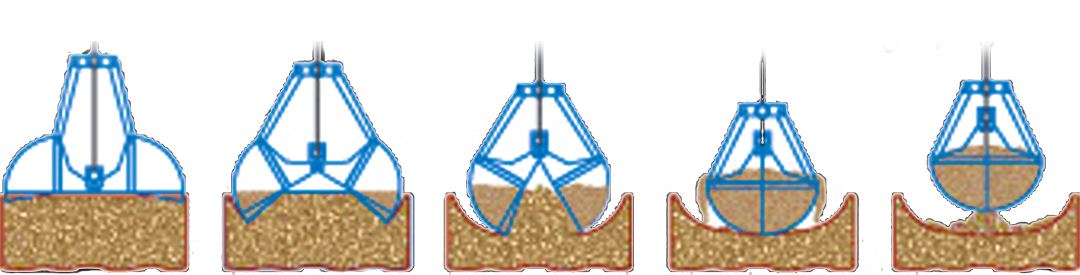

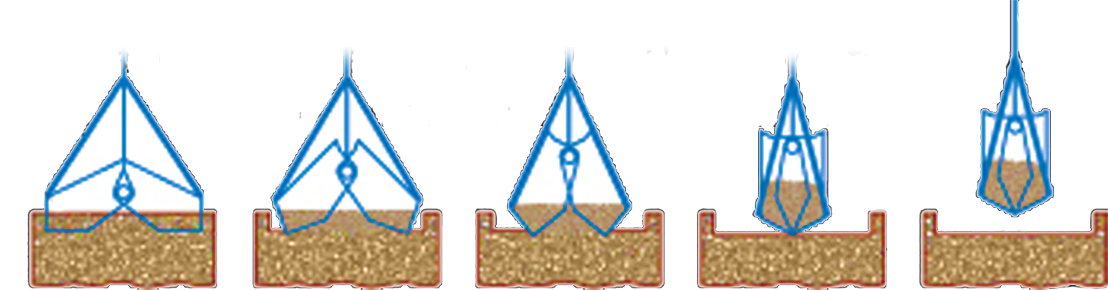

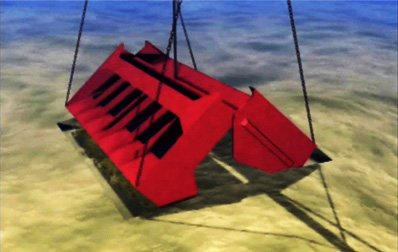

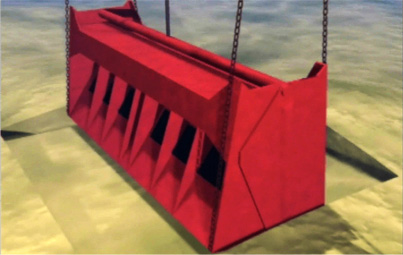

Cable Arm® Environmental clamshells remove material at almost the same water content and volume as in-situ materials. Excess clean water in the clamshell is drained through vents located above the sediment water interface. The passive venting system also minimizes downward pressure, seals in material, and prevents water from washing contaminated sediment out of the bucket.

Cable Arm® Environmental clamshells remove material at almost the same water content and volume as in-situ materials. Excess clean water in the clamshell is drained through vents located above the sediment water interface. The passive venting system also minimizes downward pressure, seals in material, and prevents water from washing contaminated sediment out of the bucket.

Overlapping steel side plates ensure minimal lateral movement of material and reduce side sediment windrowing from the bucket discharge by reducing the cross-sectional area during bucket closing. The overlap offset of the side plate is located at 27-29º past the closing centerline, on each end of the bucket. Rubber seals, set within the U-shape grooves, help seal off water flow and help prevent the release of material from inside the bucket.

Overlapping steel side plates ensure minimal lateral movement of material and reduce side sediment windrowing from the bucket discharge by reducing the cross-sectional area during bucket closing. The overlap offset of the side plate is located at 27-29º past the closing centerline, on each end of the bucket. Rubber seals, set within the U-shape grooves, help seal off water flow and help prevent the release of material from inside the bucket.

The material’s center of mass is located below the center of the bucket’s containment area. This low center of gravity decreases sediment overflow at the ends of the bucket during closure. Gravity’s lateral outflow effect on sediment will also be minimized when the bucket’s width is wider than the bucket’s length giving it an over square design. In addition, the top of the bucket is sealed by rubber, stopping the inflow of water into the bucket during bucket ascension. This reduces the loss of material from the bucket due to washout.

The material’s center of mass is located below the center of the bucket’s containment area. This low center of gravity decreases sediment overflow at the ends of the bucket during closure. Gravity’s lateral outflow effect on sediment will also be minimized when the bucket’s width is wider than the bucket’s length giving it an over square design. In addition, the top of the bucket is sealed by rubber, stopping the inflow of water into the bucket during bucket ascension. This reduces the loss of material from the bucket due to washout.

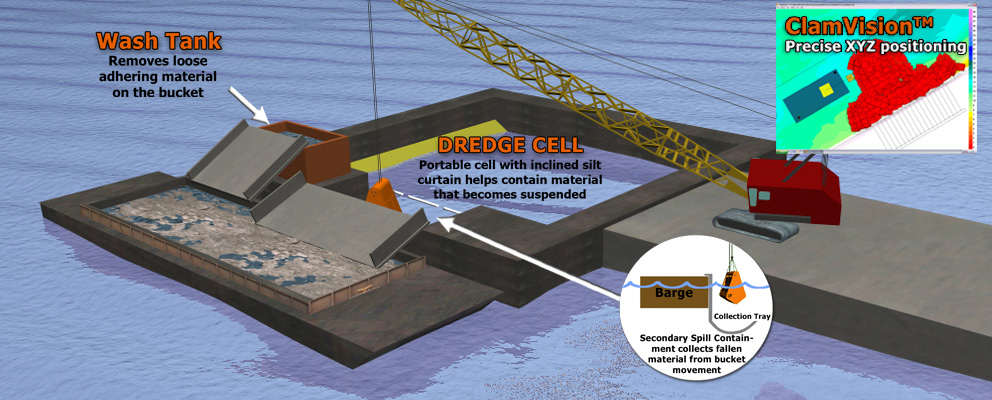

Conventional clamshells leave an uneven surface with potholes that can hold contaminants. Patented Level-Cut® technology creates a nearly flat rectangular cut, ideal for even removal of sediment. Contamination in waterways is typically limited to soft sediment. Cable Arm clamshells can “scrape” along compacted virgin sands, removing only the contaminated sediment resting on top.